Equipment and Capacity

Laser Cutting

Our Amada LC3015X1 4kW, flying optic, flatbed laser processes mild steel, stainless steel and aluminium sheet up to a maximum size of 3000mm x 1500mm and a maximum plate thickness of 20mm (mild steel).

Forming

Our LVD PPEB-8 110 tonne, 8-axis pressbrake can process components up to 3m long and is equipped with a CADMAN Touch controller to facilitate rapid setup and turnaround times for components.

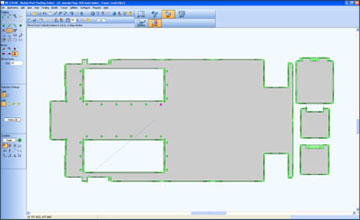

CAD/CAM

Our Radan 2D & 3D system allows us to quickly and easily:

- Import your CAD data

- Convert any 3D components to flat patterns

- Create tool paths on the resulting part data

- Nest components on sheet material in order to maximise material usage

- Generate NC code to drive the laser

In addition, 3D CAD data can be exported directly to the pressbrake in order to minimise setup times.

General

You may have components which require secondary operations, such as tapped or countersunk holes. You may require your components to be finished by powdercoating or plating. We can arrange this for you if required and deliver a finished component. Contact us for more information.